Planet

We are proactively managing our impact on the environment with a prioritization on circularity and reducing greenhouse gas emissions.FY25 Planet highlights

We are advancing our work to be responsible stewards around reducing our scope 1+2 emissions, reducing waste and recycling water. We set near-term targets and include funds in regional budgets. We are strengthening our business operations and company culture to drive progress at the local level. As a result, the entire organization is engaged in and committed to our goals.

MINIMIZE OUR IMPACT

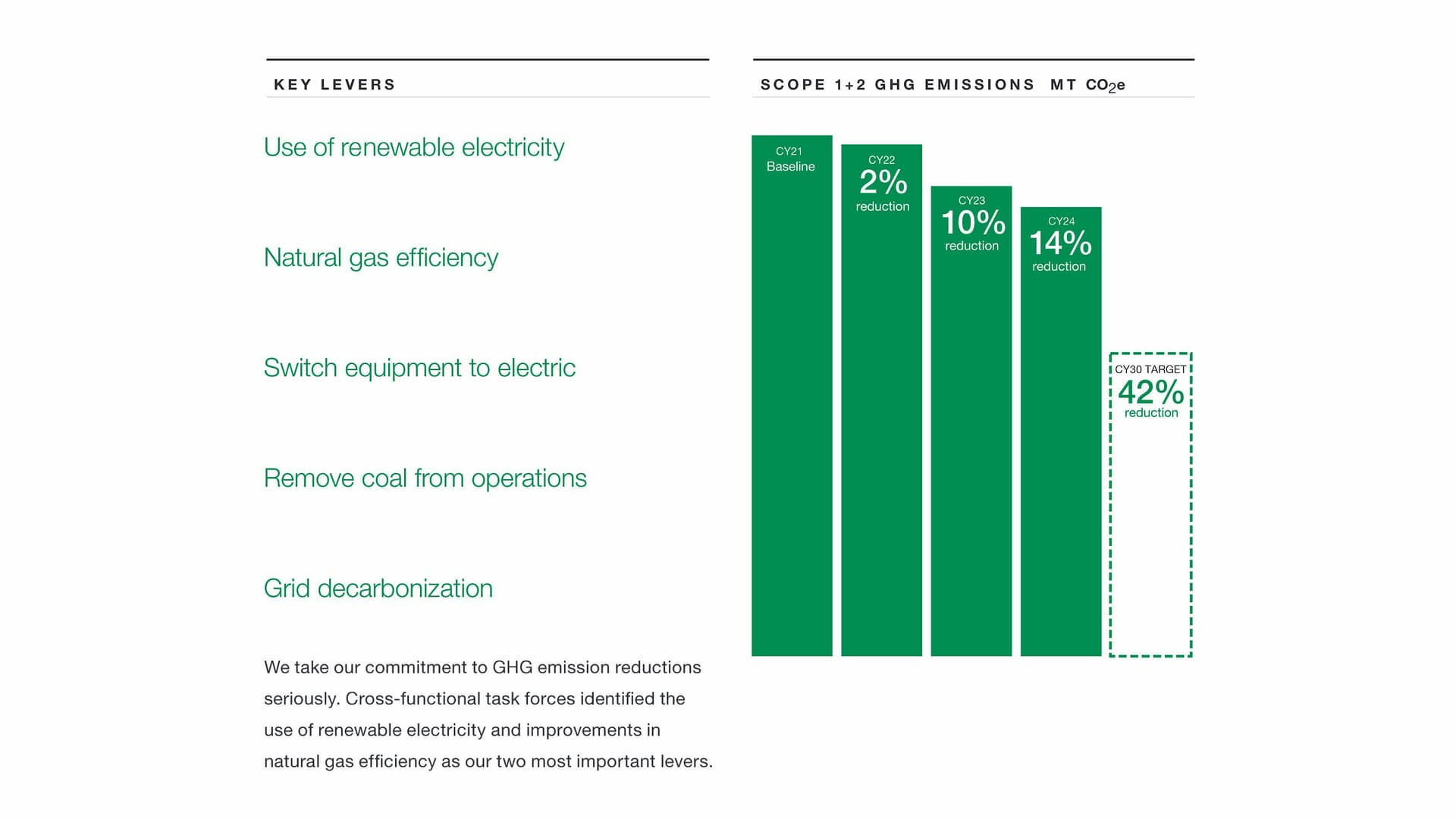

Reducing our Scope 1+2 carbon footprint

Based on the path we charted to reduce our Scope 1+2 greenhouse gas (GHG) emissions and work toward net zero by 2050, we focused on the two biggest levers — the use of renewable electricity and natural gas efficiency in our facilities. To underscore that these are company goals, we also set short-term internal goals (FY25-FY27) for each region, owned by the leadership team and cascaded throughout the organization. These goals help drive both action and accountability across all facets at James Hardie.

SUSTAINABILITY IN ACTION

Reducing emissions

Our teams continue to engage through demonstrating sustainability in action. Ryan Thompson, maintenance manager at Tacoma 1, reduced energy usage by idling assets when not in use, delivering annual savings and reducing annual energy consumption. Energy efficiency also contributes to reducing our carbon footprint and helps save on utility bills. In our refurbished Carole Park Finishing offices, Jason Hawkins, PCI manager, installed new electrical distribution boards to the highest safety standards. He also networked our LED lighting and air conditioning with automation systems including time and motion detection, reducing our energy usage.

SUSTAINABILITY IN ACTION

Recycling process waste for reuse in fiber cement production

Our cross-functional RTY (rolled throughput yield) Improvement Team in Rosehill, Australia, developed and implemented technology to recycle dust created during the low-density additive process back into our fiber cement manufacturing. This process eliminates the equivalent of 200 metric tons of dust per year from landfill and saves an estimated AU$80,000 a year in waste costs.

MINIMIZE OUR IMPACT

Optimizing water conservation

We are raising the bar and setting new internal standards that go beyond regulatory requirements as we pursue water recycling opportunities as appropriate by site. We continue to invest in the development of advanced technology to manage our water use and reduce wastewater discharge, including ways to incorporate treated wastewater into our production processes. These actions improve our operational capabilities while building resilience in the communities where we live and operate, doing the right thing for the environment and reducing our costs.